Quality, traceability, and regulatory compliance with zero margin for error

Technology that inspects like an expert and works like a machine.

In the pharmaceutical industry, quality control is not optional—it is critical. Every package, code, and dosage must be verified 100%, without exceptions. Our artificial vision and deep learning solutions ensure precise, traceable, and fully automated processes, helping you meet the most demanding industry standards.

Key Benefits for the Pharmaceutical Industry

- High-resolution visual inspection for every product

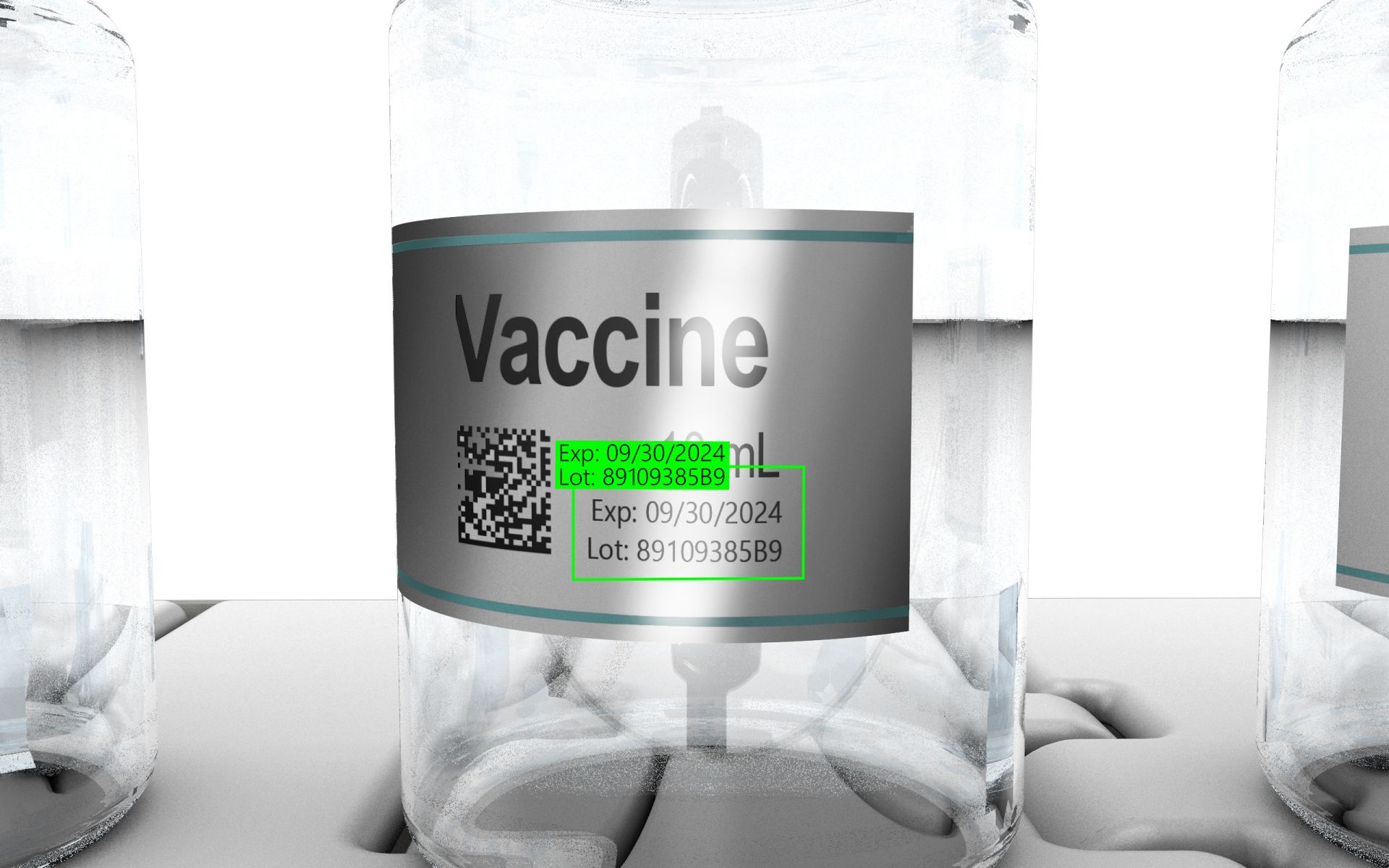

- OCR reading and verification of expiry dates and batch numbers

- Complete traceability of codes (1D, 2D, DataMatrix, QR)

- Fill, cap, and label control

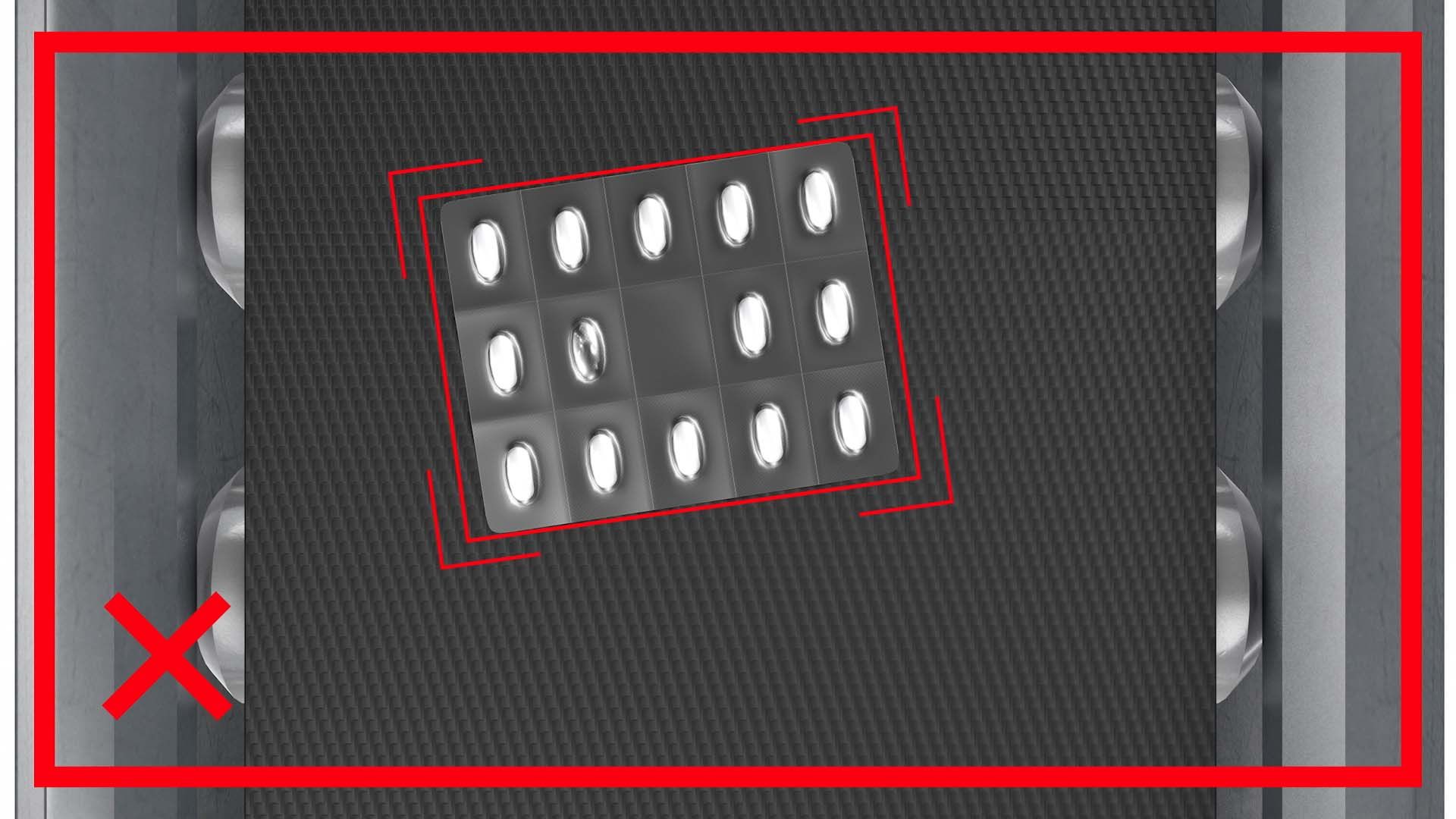

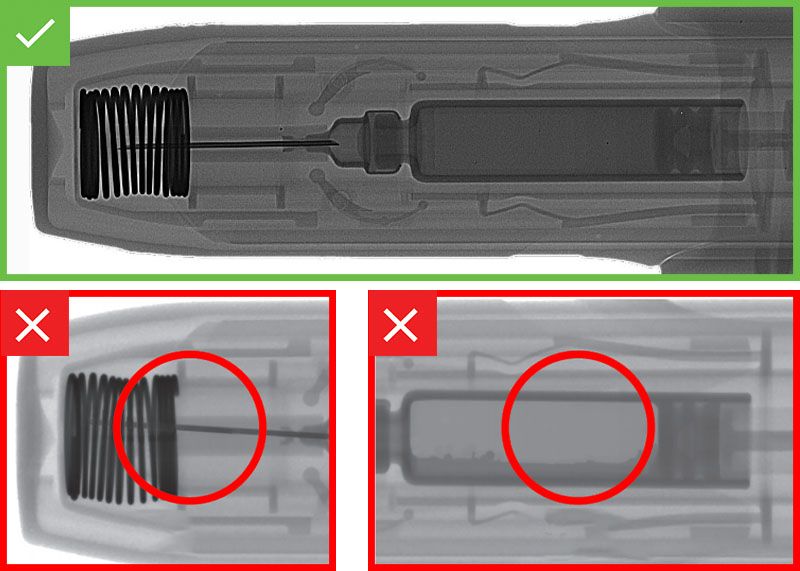

- Detection of foreign objects or misplaced elements

- Automatic rejection of defective products

Critical Applications

- Verification of caps, labels, and blisters

- Control of containers on high-speed lines

- 360º inspection of vials and cylindrical ampoules

- Print verification: expiry, batch, and product information

- Automated traceability for GMP/ICH compliance

Designed for Your Production Environment

- Integration with SCADA, ERP, or MES systems

- Interfaces validated according to industry standards

- Inline or standalone installation

- Hygienic design and materials compatible with cleanrooms

Artificial intelligence for smarter inspection

Not all defects are the same. With AI, our systems learn to distinguish valid products from non-conforming ones, even in complex scenarios: misaligned labels, blister bubbles, or minor printing defects. Where other systems fail, AI learns and continuously improves.

Results That Make a Difference

- Fewer errors and rework

- Complete traceability from production to customer

- Increased productivity without compromising quality

- Faster audits and always-available data