Millimetric Precision in Electronic Component Manufacturing

The electronics industry is synonymous with innovation and miniaturization, but also with extreme demands for quality and efficiency. From microchips to consumer devices, every component must be flawless. At Bcnvision Group, we develop advanced machine vision and Artificial Intelligence solutions that ensure maximum precision and reliability—critical for the manufacturing of PCBs, SMD components, and finished devices.

Specialized Solutions for Electronics

Our technology enables the automation and optimization of critical processes, ensuring the integrity and functionality of your electronic products.

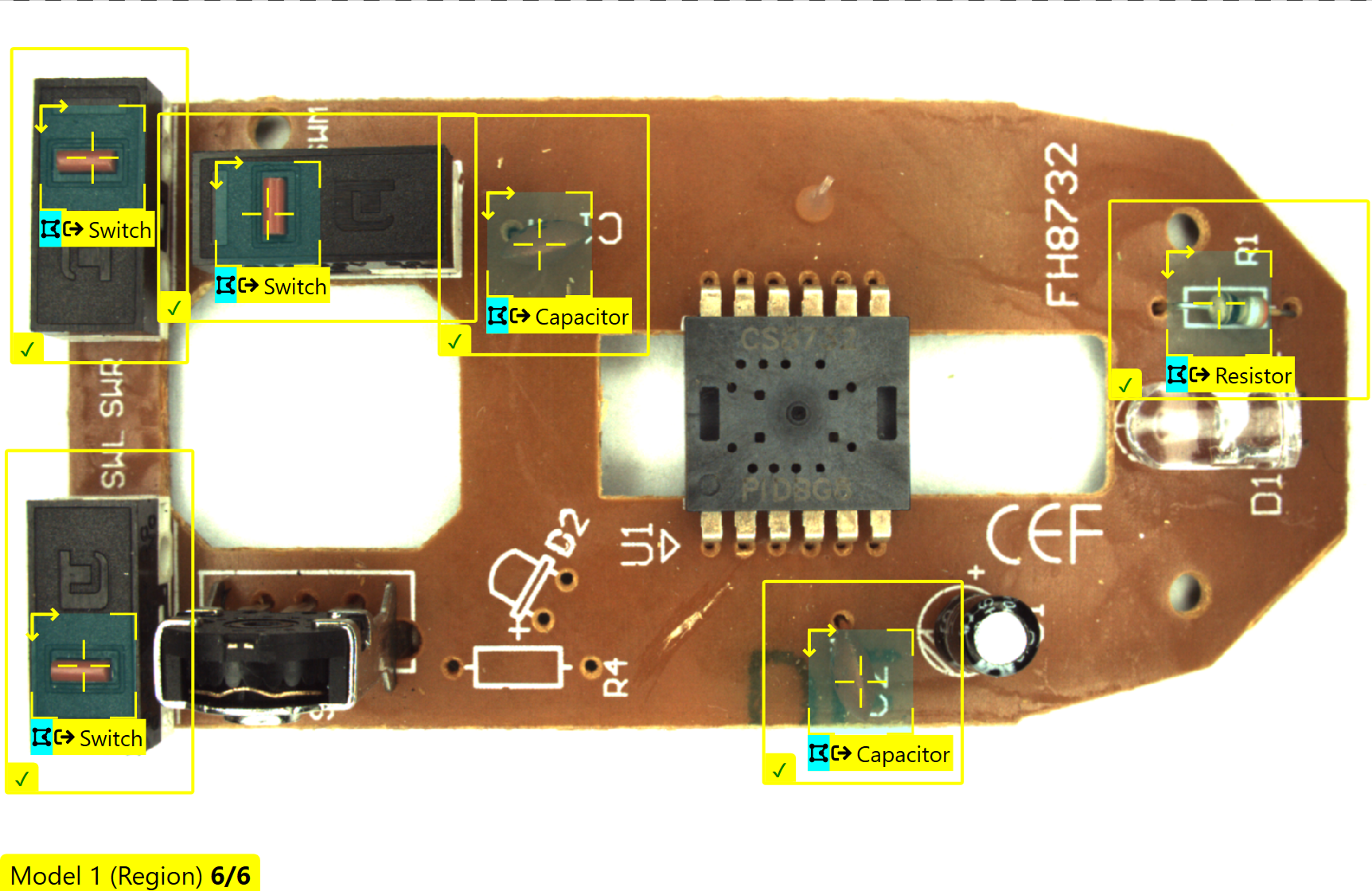

1. Component and PCB Inspection

We ensure correct placement and the absence of defects on every board and component.

- Solder joint inspection (AOI): Detection of solder bridges, insufficient paste, excess or lack of solder, and lifted leads.

- SMD component verification: Presence, position, polarity, and value control of components (resistors, capacitors, ICs).

- Pad and trace inspection: Detection of short circuits, open circuits, or damage on printed circuit boards.

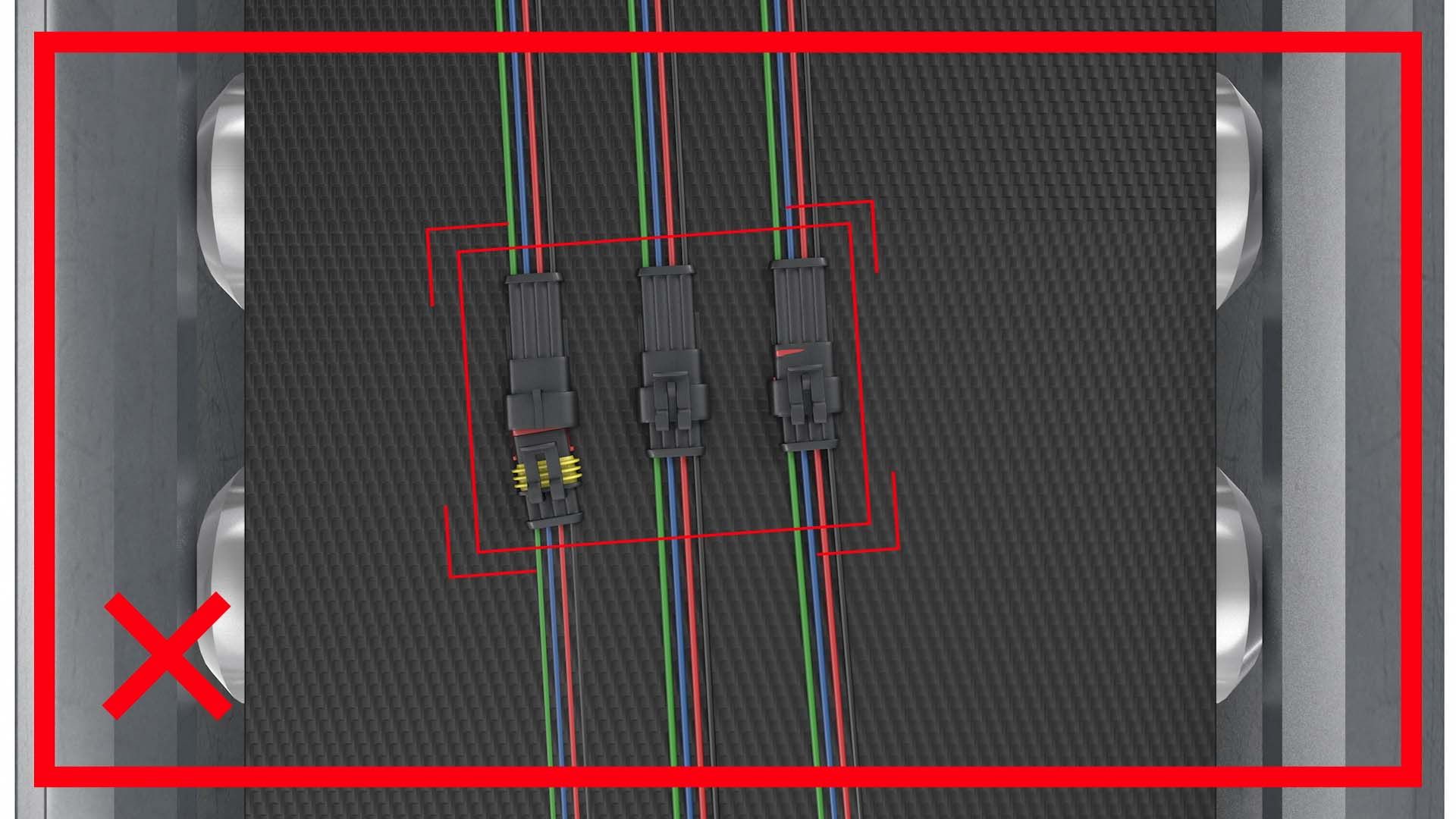

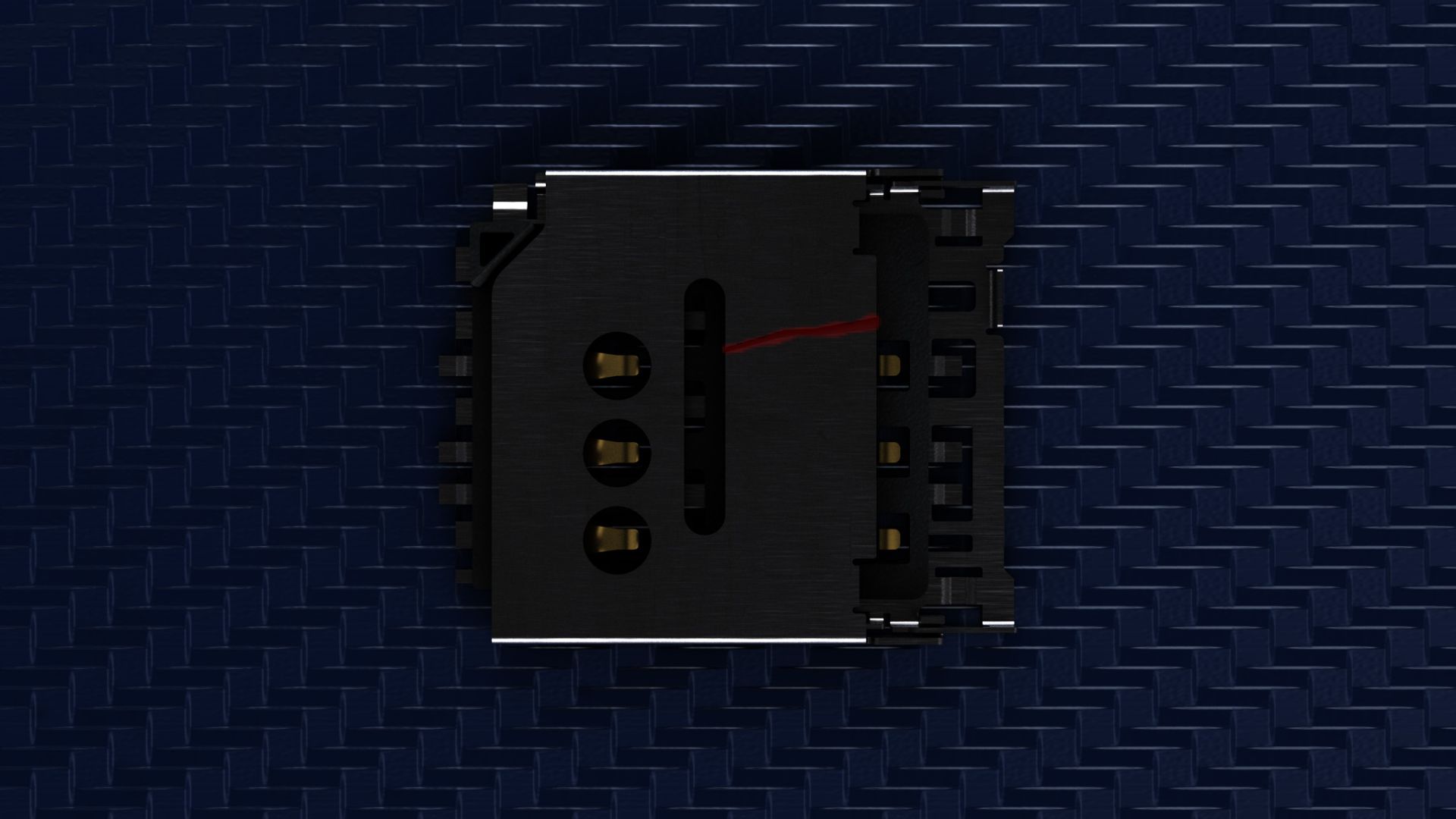

- Connections and connectors: Verification of bent pins, correct connector assembly, and proper fastening.

2. Dimensional Control and Precision Metrology

Accurate measurements to ensure functionality and perfect assembly.

- Pitch and alignment measurement: Verification of pin spacing in connectors and lead alignment in ICs.

- Solder Paste Inspection (SPI): 3D inspection of paste volume and profile to ensure optimal soldering.

- Assembly control: Tolerance verification in housings, displays, and other components of the final device.

3. Electronic Traceability and Serialization

End-to-end supply chain management and quality control.

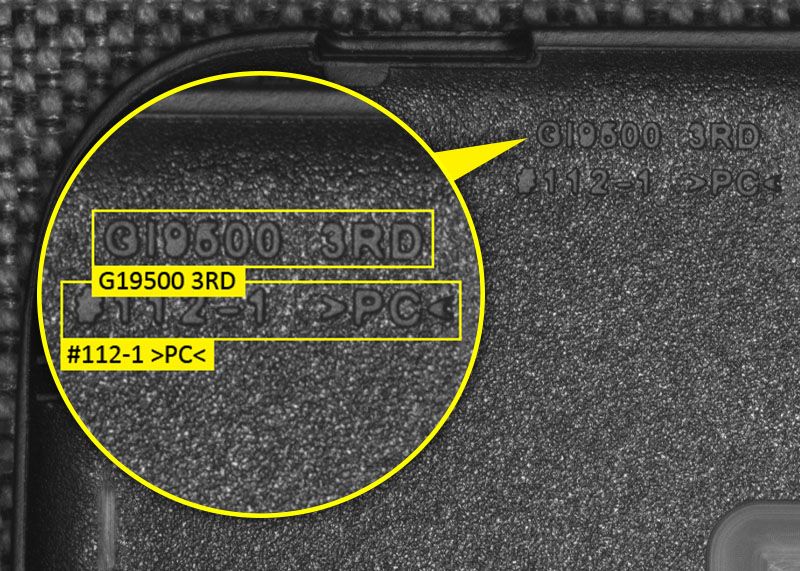

- 2D code reading (Data Matrix, QR) and 1D (barcodes): Identification of components on any surface and size, including directly on PCBs.

- Laser marking and OCR/OCV: Verification of legibility of engraved or printed characters on microchips, housings, or labels.

- Product serialization: Assignment and reading of unique serial numbers for batch control and anti-counterfeiting.

4. Robot Guidance for Assembly and Soldering

Flexible automation for highly complex assembly processes.

- Precision assembly: Robot guidance for the placement of small or delicate components.

- Selective soldering: Robot orientation for specific soldering points on PCBs.

- Wafer and microchip handling: Vision systems for ultra-precise positioning in cleanroom environments.

The Added Value of Bcnvision Group

- Artificial Intelligence: Advanced solutions to inspect complex aesthetic defects or classify components based on subjective criteria.

- Cortex Software: A comprehensive management platform that centralizes control of your vision systems through an intuitive and scalable interface.

- Industry 4.0 Integration: Our systems communicate with your plant’s MES and PLCs, providing real-time data to optimize decision-making and improve overall efficiency.

- Electronics Experts: Deep knowledge of IPC standards and global electronics industry quality requirements.

Success Stories in Electronics

- SMD Component Manufacturer: 100% automated inspection of polarity and presence on high-speed assembly lines.

- PCB Assembler: Intelligent AOI system for early detection of solder defects, dramatically reducing rework.

- Medical Device Company: Full traceability of critical electronic components through DPM code reading.