"Zero Defect" Inspection and Quality Control in High-Precision Parts

The turning industry is characterized by the mass production of complex, high-precision parts, where repeatability and zero-tolerance for defects are critical. From small screws and pins to components for sectors such as automotive, medical, or aerospace, the quality of each part is fundamental. At Bcnvision Group, we develop advanced machine vision and Artificial Intelligence solutions that ensure thorough inspection and rigorous quality control at every stage of the turning process, guaranteeing the reliability and performance of your products.

Specialized Solutions for Turning

Our technology automates and optimizes the inspection of turned parts, improving efficiency and reducing defect-related costs.

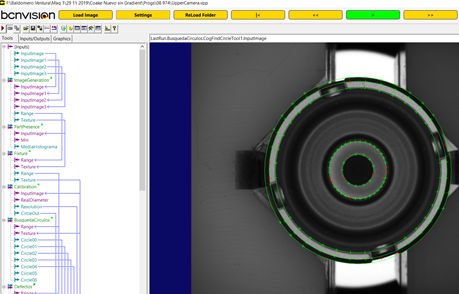

1. High-Precision Dimensional Control

Non-contact verification of critical tolerances in complex parts.

- 2D and 3D Measurement: Checking diameters, lengths, angles, radii, threads, and the presence/absence of chamfers or drilled holes.

- Complex Shape Inspection: Analysis of machined part profiles, detecting minimal deviations.

- Thread Verification: Control of pitch, depth, and flank of internal and external threads.

2. Surface Defect Detection

Identification of imperfections that compromise part quality and functionality.

- Aesthetic and Functional Defects: Detection of scratches, tool marks, burrs, micro-cracks, pores, and discolorations.

- 360º Inspection: Systems with multiple or rotating cameras to inspect all faces of the part.

- Surface Finishes: Verification of surface treatments such as chrome plating, anodizing, or hardening.

3. Part Traceability and Serialization

Complete control over the origin and destination of each component.

- DPM (Direct Part Marking) Code Reading: Identification of codes laser-engraved, dot peened, or micro-percussed on metal surfaces.

- OCR/OCV: Verification of the readability of batch numbers, references, and manufacturing dates engraved or printed.

- Classification and Sorting: Vision systems for automatic classification of parts by type, size, or quality.

4. Robot Guidance for Feeding and Sorting

Intelligent automation in the handling of turned parts.

- 3D Bin Picking: Extraction of disorganized parts from bins for precise feeding to machines or assembly lines.

- Positioning: Robot guidance for orienting and loading parts in subsequent processes (e.g., machining, grinding, assembly).

- Feeding Control: Verification of correct part orientation in vibratory feeders or magazines.

The Added Value of Bcnvision Group

- Artificial intelligence Technology: Ability to inspect subtle or aesthetic defects that traditional systems cannot identify, improving control robustness.

- Cortex Software: Centralized and scalable management platform for all your vision systems, with an intuitive and user-friendly interface.

- Industry 4.0 Integration: Our systems are designed to communicate seamlessly with your plant's PLCs and MES systems, providing real-time data for efficient production management.

- Turning Expertise: We understand the specificities of the sector and the quality demands of short and long series production.

Success Stories in Turning