SAT was founded in 1966 in Durango as Sociedad Anónima de Tuercas. Today, the company specializes in the production of special parts mainly for the automotive industry and is composed of three companies, with two plants in Spain and one in Romania. Estamcal handles forging and heat treatment. In 1998, Mecanifran was created about 3 km from Estamcal to offer machining services and provide greater added value to clients. In 2007, Actiro was founded, with a plant in Romania, aiming to machine parts for customers in that region.

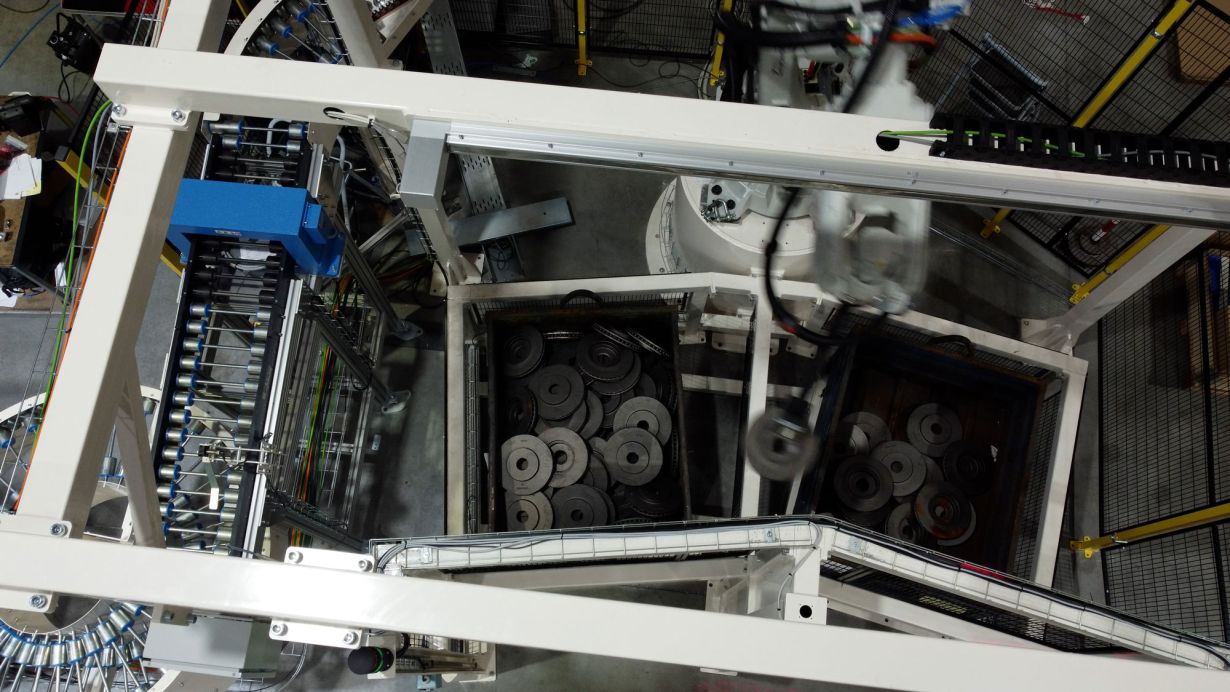

The company stands out for its manufacturing capabilities, including Hatebur forging machines, ovens for various heat treatments, and sophisticated machinery for machining high-volume parts. Typically, vertical forging is used, but at Satuerca, special horizontal forging machines achieve higher production speeds. Vertical forging machines can operate between 15 and 45 strokes per minute, while some machines in the group reach up to 180 strokes per minute.

The main products include bearing rings, gearbox gears, clutch cores, assembly nuts, and cams, although they also manufacture other non-automotive components.

SAT measures product quality and traceability, guaranteeing zero defects in parts delivered to customers, and Bcnvision has contributed to this effort, specifically in surface and dimensional inspection of forged parts using 2D and 3D vision systems.

Bcnvision became a partner of Satuerca in 2009, with a bold and ambitious proposal for the time, resulting in high satisfaction and excellent collaboration for both companies.

The solutions developed by Bcnvision include the inspection of different types of parts, detecting surface and edge impacts, incomplete fills, and performing dimensional analysis simultaneously. Both facilities begin at a station with high-resolution 2D Cognex cameras with backlighting, sending precise coordinates to multiple Staübli robots to pick up the parts and move them to the next station.

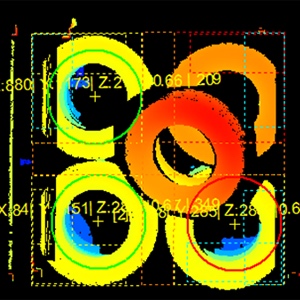

At the laser station, three Smart Ray scanners perform 3D surface inspection with 0.1 mm accuracy. Two scanners inspect the top and bottom surfaces in fixed positions, while the third inspects the “rolling band”, the lateral area of the part. This occurs while the part rotates 360º around its axis.

To capture rotation information, the cameras acquire the part line by line around its perimeter, with rotation data managed by an encoder. Up to five types of defects can be analyzed in less than one second, while simultaneously performing dimensional verification to ensure correct profile measurements. This application is also adapted for different part formats.

Result: perfect parts and satisfied customers! At Bcnvision, we are proud to be part of success stories like this. Thank you for trusting Bcnvision.