INGENERSUN is an engineering company specialized in the automation and robotization of industrial processes, located in Zamudio, Vizcaya.

INGENERSUN’s turnkey automation projects provide fully customized solutions to meet clients’ needs. Its multidisciplinary team, with extensive experience in the sector, allows INGENERSUN to deliver tailored solutions in all aspects of a project.

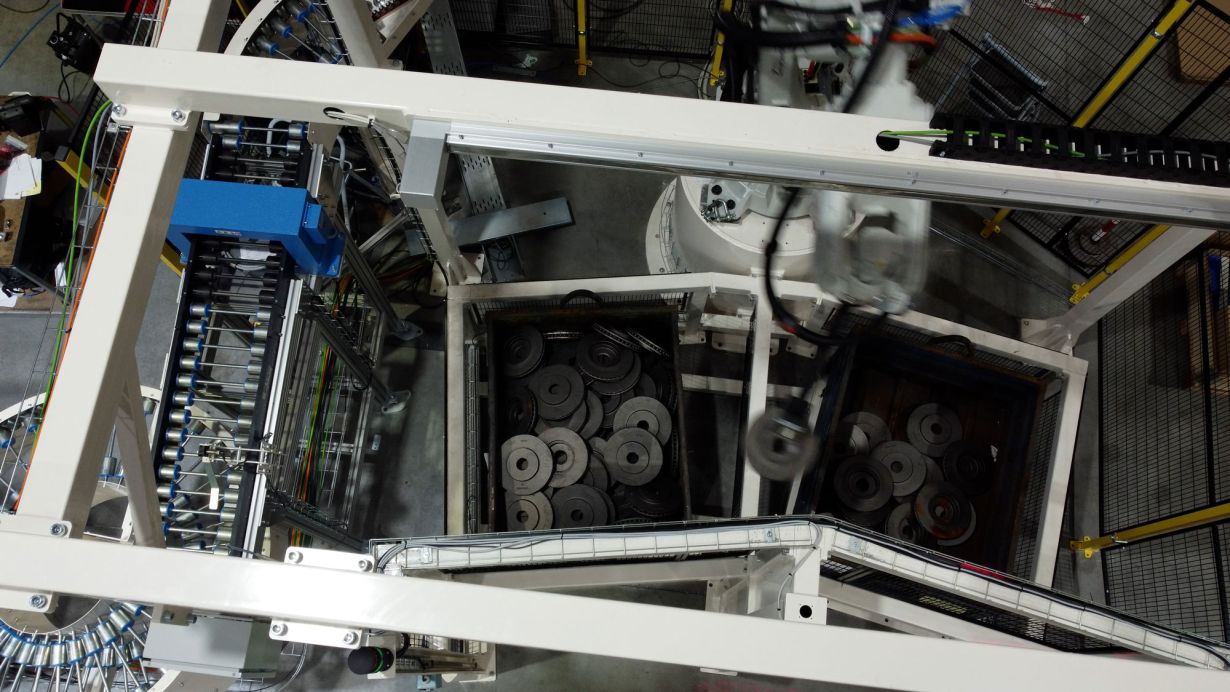

INGENERSUN manages projects from start to finish, ensuring high flexibility in design and rapid response to adapt the solution to each client’s specific requirements. In this case, we present the universal tire depalletizing solution developed by Ingenersun with a vision system created by Bcnvision. The success story focuses on bin picking of tires using an anthropomorphic robot and 3D machine vision.

This universal tire depalletizer operates on:

- A 15-meter track

- 6 unloading bays

- Maximum pile height of 1600 mm

- Multi-reference

- Barcode identification via readers

- Automatic trajectory correction for misaligned columns Individual bay status signaling

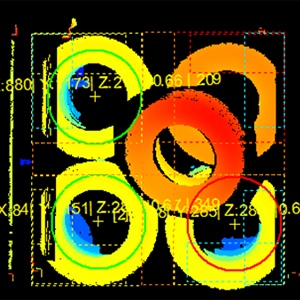

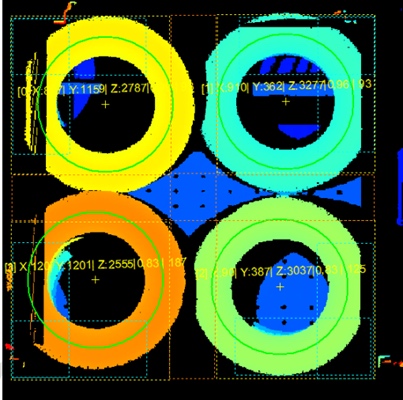

The machine vision solution is based on 3D acquisition technology and includes a Photoneo acquisition device, which generates a point cloud through laser pattern projection and corresponding reconstruction algorithms developed by Bcnvision according to Ingenersun’s requirements.

This technology produces a precise point cloud with a wide field of view, allowing it to be implemented in a wide variety of situations.

Once the robot is in a nominal position, the vision system acquires the data, resulting in a point cloud that is processed to obtain coordinates (x, y, z).

These coordinates are sent to the PLC, which processes them and generates an optimized unloading strategy based on an algorithm designed to pick without colliding with the container or gripper. The robot then positions itself over the center of each column and performs a complete unload, including a trajectory correction system to absorb variations in tire placement along the column.

The robot is mounted on a track that allows it to move between several locations reserved for tire container placement (called bays) and to unload continuously. Both the robot and the acquisition device are mounted on the track, offering two main advantages:

- Single calibration using an element located on the platform, required only the first time or after significant hardware changes.

- Optimizing the cycle by processing the next container while unloading the current one.

The system has been developed considering two possible container layouts:

- Square distribution

- Triangular distribution, considering all orientation possibilities

These layouts allow the addition of anomaly detection that could interfere with the robot’s trajectories during the unloading sequence.

Detected anomalies include:

- Fallen tires in critical areas

- Columns with tires tilted beyond the accepted range

- Overlapping tires

The detection and coordinate acquisition system is configured for different container types, which may vary the reference planes. Different algorithms are also generated based on the inner diameter of each predefined reference, ensuring high precision in calculations.

In addition to the depalletizer, there is a second station dedicated to automatically stacking tires, multi-reference, without manual adjustments, and with adjustable cadence. Below, you can watch the video of this success story, kindly provided by Ingenersun.