Intelligent Reading of Complete Pallets with Machine Vision for Logistics Traceability

Ingimec, an engineering company specialized in custom machinery, robotic integration, and machine vision systems, collaborates with industrial companies to optimize and control high-demand production and logistics processes.

In this case study, Ingimec worked together with Nevitec Vision Technologies, part of the Bcnvision Group, to develop an advanced machine vision solution called “Pallet Scanning”, aimed at automatically reading barcodes on all four sides of a complete pallet.

Initial Situation

Reading barcodes on complete pallets is critical to ensure traceability, logistics control, and proper product management in industrial environments. However, traditional systems often require line stoppages, additional handling, or partial readings, directly impacting operational efficiency and increasing the risk of errors.

Ingimec faced the challenge of improving the reliability and speed of this process by integrating a solution that could operate continuously without disrupting the production flow.

The Challenge

The main challenge was to develop a system capable of:

- Simultaneously and accurately reading barcodes on all four sides of a pallet.

- Operating in real-time without stopping the line or altering the existing workflow.

- Maintaining high reading reliability even under demanding industrial conditions.

- Integrating easily into existing production lines and industrial control systems.

The Solution: Pallet Scanning

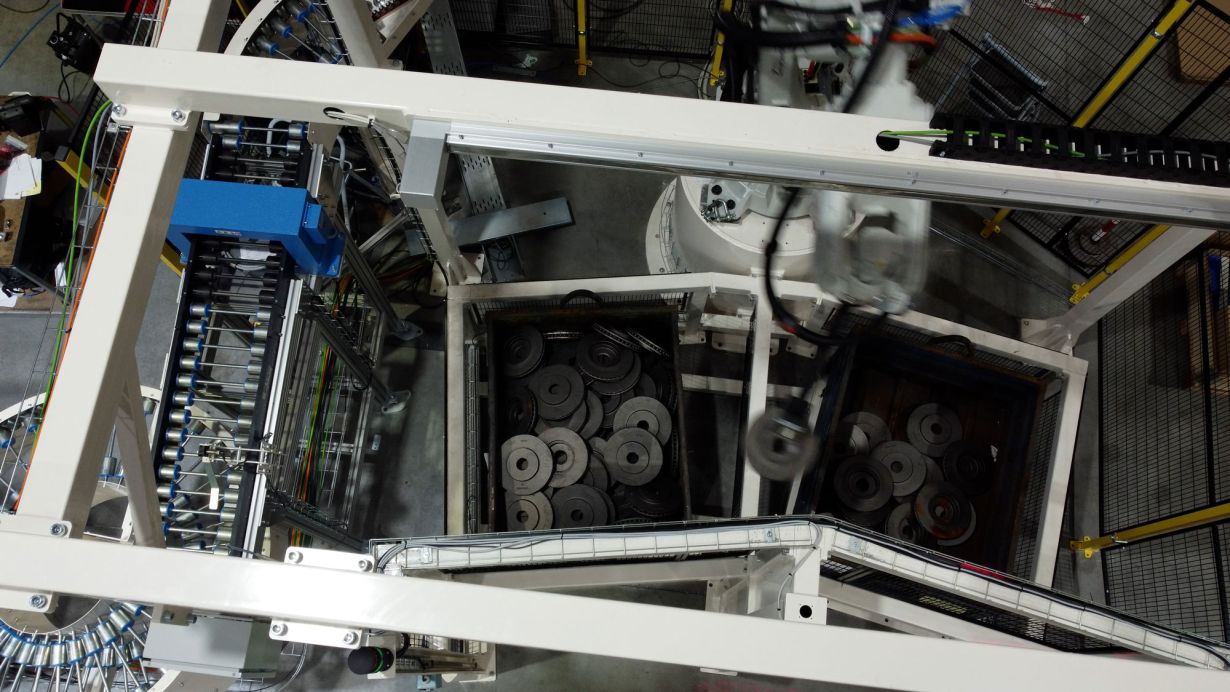

To address this challenge, Nevitec Vision Technologies, in collaboration with Ingimec, developed Pallet Scanning, a machine vision system specifically designed for logistics and in-line packaging applications.

The solution is based on:

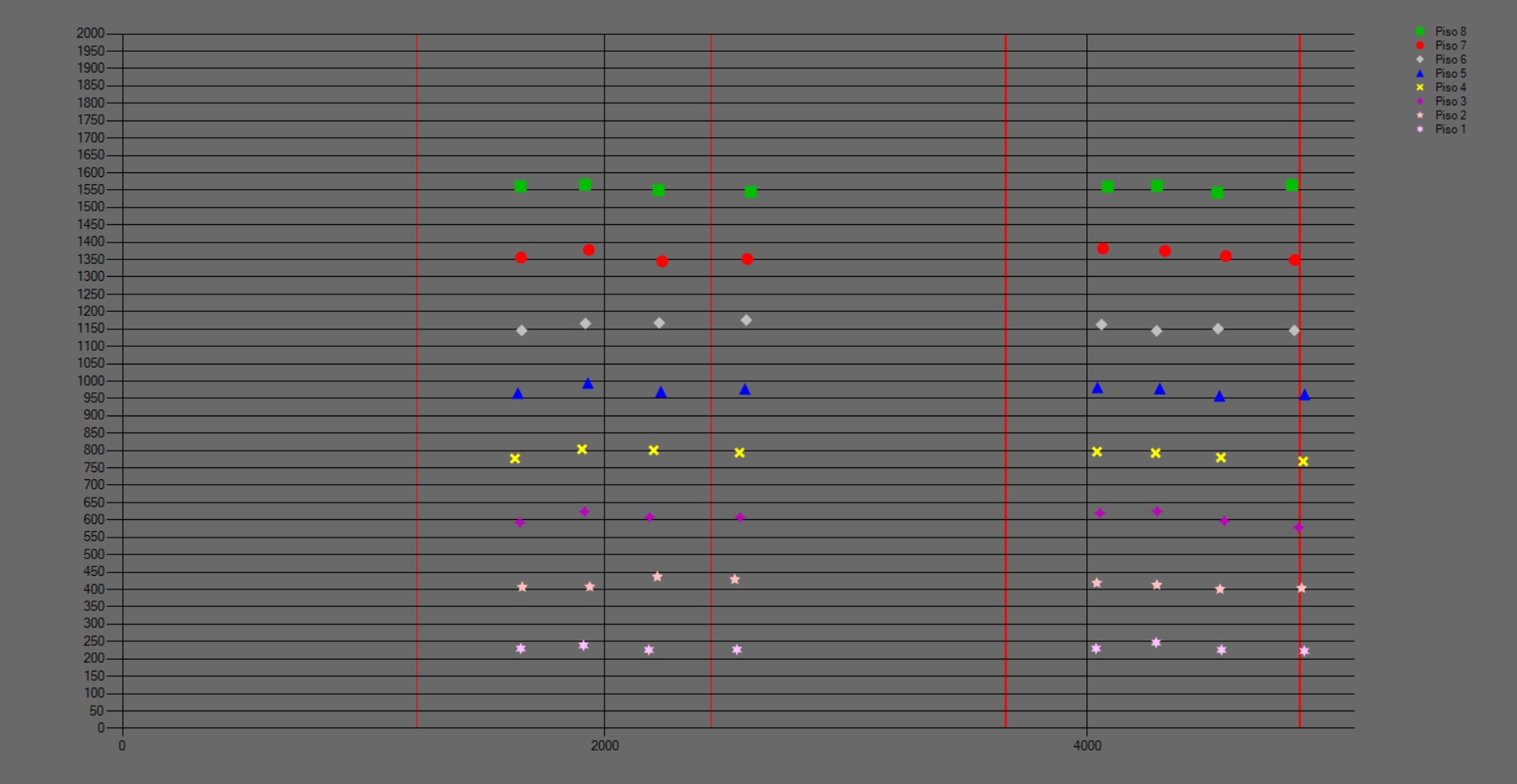

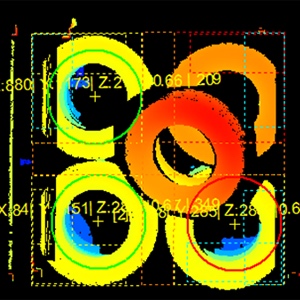

- High-resolution industrial cameras strategically positioned to cover all four sides of the pallet.

- Advanced image processing algorithms capable of detecting and decoding barcodes in real-time.

- Direct integration with the control system, allowing the vision data to be used immediately for product management and traceability.

This architecture enables complete pallet reading without stoppages, reprocessing, or manual intervention.

Results and Benefits

The implementation of Pallet Scanning has enabled Ingimec to:

- Significantly increase the efficiency of barcode reading processes.

- Improve the accuracy and reliability of logistics traceability.

- Reduce errors associated with incomplete or manual readings.

- Optimize packaging and shipping flow without affecting line performance.

This project demonstrates how intelligently applied industrial machine vision can solve complex challenges in real production environments, delivering immediate value in efficiency, quality, and process control.