MITEC ENGINY, a company dedicated to the automation of industrial production processes with over 15 years of experience in the sector, has designed a machine to optimize a manual manufacturing process for Isotubi. Isotubi is a company specialized in the production of welded stainless steel tubes and fittings for more than 40 years. To successfully develop the machine, several companies collaborated with MITEC ENGINY, including Bcnvision for all aspects related to machine vision and Stäubli for part handling.

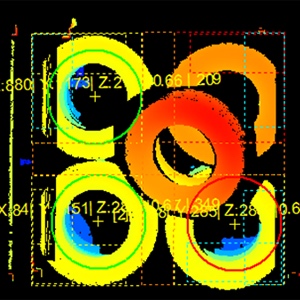

The process carried out by the machine is as follows: individual parts are picked from a container, where they are arranged chaotically, and placed into the Isotubi machine’s forming dies. Once formed, the parts are checked to ensure that the forming dimensions are within tolerance, and then placed in the corresponding box.

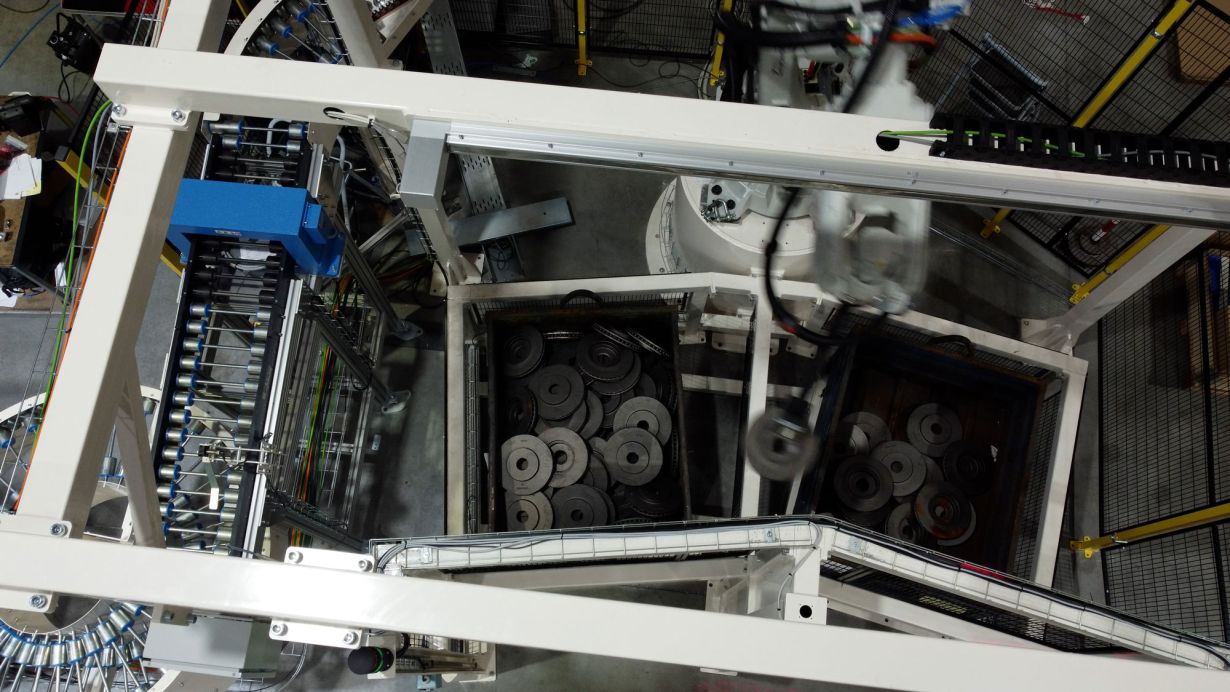

The machine consists of two main sections:

Bin Picking Station and Part Handling Station

The Bin Picking station includes a 3D scanner by PHOTONEO, which detects the parts inside the container, analyzes which can be picked by the robot, and calculates the trajectories. The robot used is a Stäubli TX2-90L.

Part Handling Station The part handling station includes a repositioning area with a Stäubli TS2-80 robot and a dimensional control station. The first step in this process is repositioning. It consists of a white polyethylene table with a backlight and a column with a Cognex IS7600M-363-50 compact camera, supplied by Bcnvision. Its operation is as follows: The TX2-90L robot transports the parts to the repositioning area. Once a part is on the table, the camera detects its orientation. If the orientation is correct, the TS2-80 robot picks it up; if not, the TX2-90L rotates the part to achieve the correct orientation.

The TS2-80 robot distributes the parts to the different substations in the handling section. Operation:

- TS2-80 picks up the part from the repositioning station based on coordinates provided by the IS7600M-363-50 camera. It moves the part to the first forming die of the Isotubi NPC4 machine, forming one face of the part.

- TS2-80 then repositions the part in the second die to form the opposite face. Once both faces are formed, the TS2-80 carries the part to the dimensional control station.

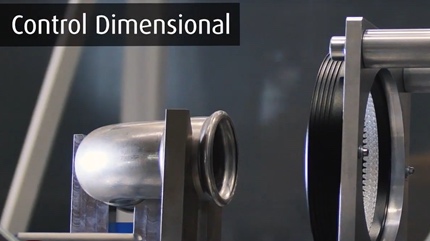

- The dimensional control station consists of a Cognex IS9912M-363-50 vision camera, its optics, a coaxial light, a backlight, and a part holding/orientation system, which allows the part to rotate for imaging both formed faces.

After dimensional control, the TS2-80 robot places the part in the finished parts container if it passes inspection, or in the scrap box if it fails.

One of the advantages of the machine is its ability to handle six different part models by simply changing the holding/orientation bases and the TS2-80 robot tool.