Baldomero Ventura is a company located in Les Franqueses del Vallès, Barcelona, with two additional subsidiaries in China and Detroit. Baldomero Ventura was founded in 1962 as a turning workshop mainly serving local customers. Since then, the company has specialized in the manufacturing of high-precision products for safety systems, continuously growing to become a global company and diversifying into other product lines for additional sectors such as medical devices.

With more than 50 years of experience in high-precision machining and turning of metal parts, especially for Tier 1 companies, the company has established itself as a preferred supplier for some of the most highly regarded industrial groups worldwide. They use the latest quality control technologies both during the manufacturing process and in the final product inspection. To ensure the highest quality delivery to their customers, they incorporate CMM machines, telecentric dimensional control cameras, high-resolution visual inspection cameras, and machine vision systems with Deep Learning.

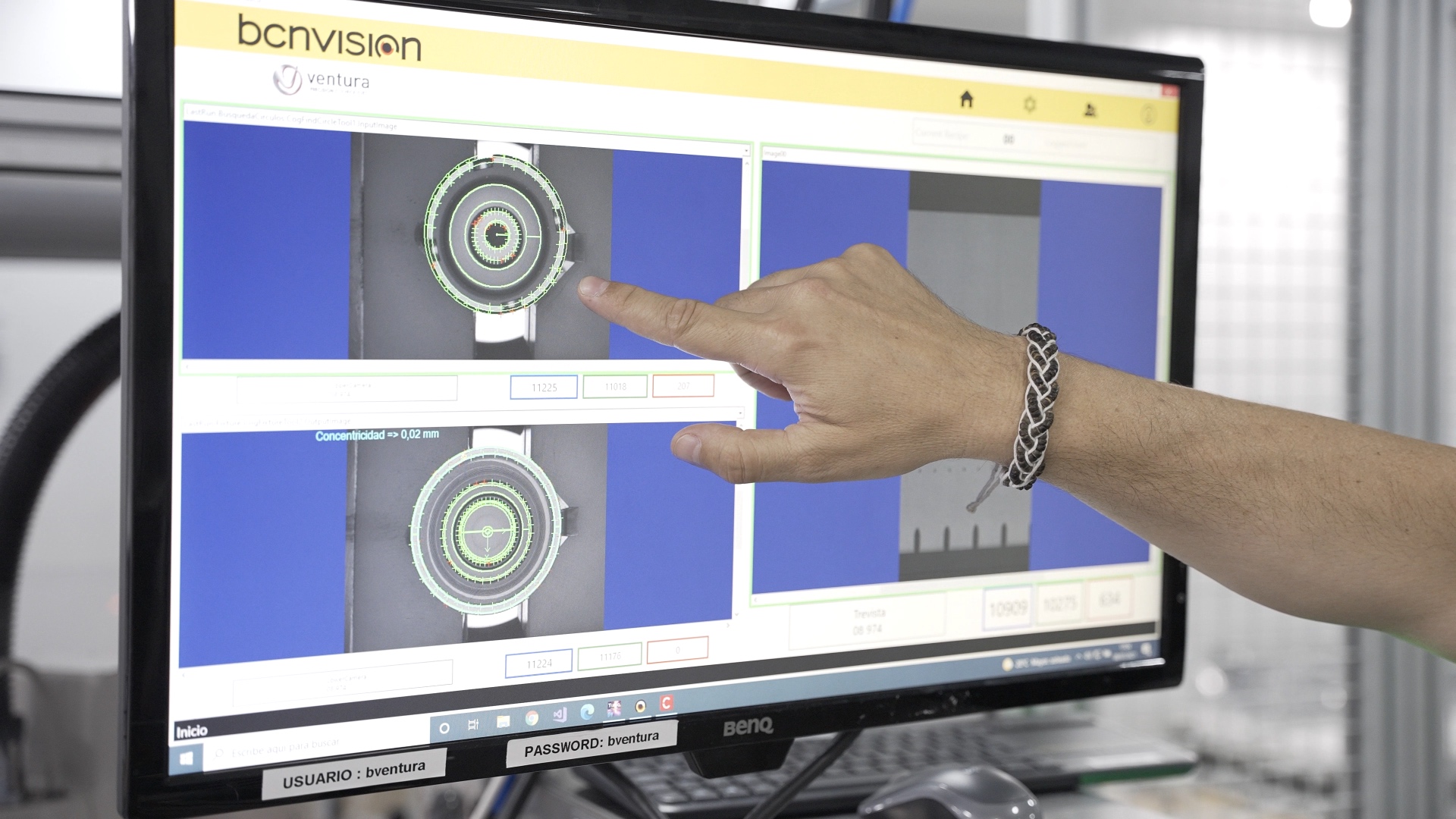

This success story focuses on the machine vision solutions provided by the Bcnvision Group. Bcnvision Group is exclusively dedicated to the design, programming, and maintenance of industrial machine vision systems. In this application for the inspection of automotive brake pistons manufactured at the Barcelona plant, the following tasks are carried out:

- Detection of surface defects on the parts: stains, impacts, chip residues, and thread inspection.

- Dimensional measurements: part length, concentricity, and hole diameters.

The objective of the project is to improve manual visual inspection, increase productivity and defect detection reliability, and reduce false rejects, thus delivering perfect parts to the final customer. Several machine vision technologies from the Bcnvision Group have been used in this project.

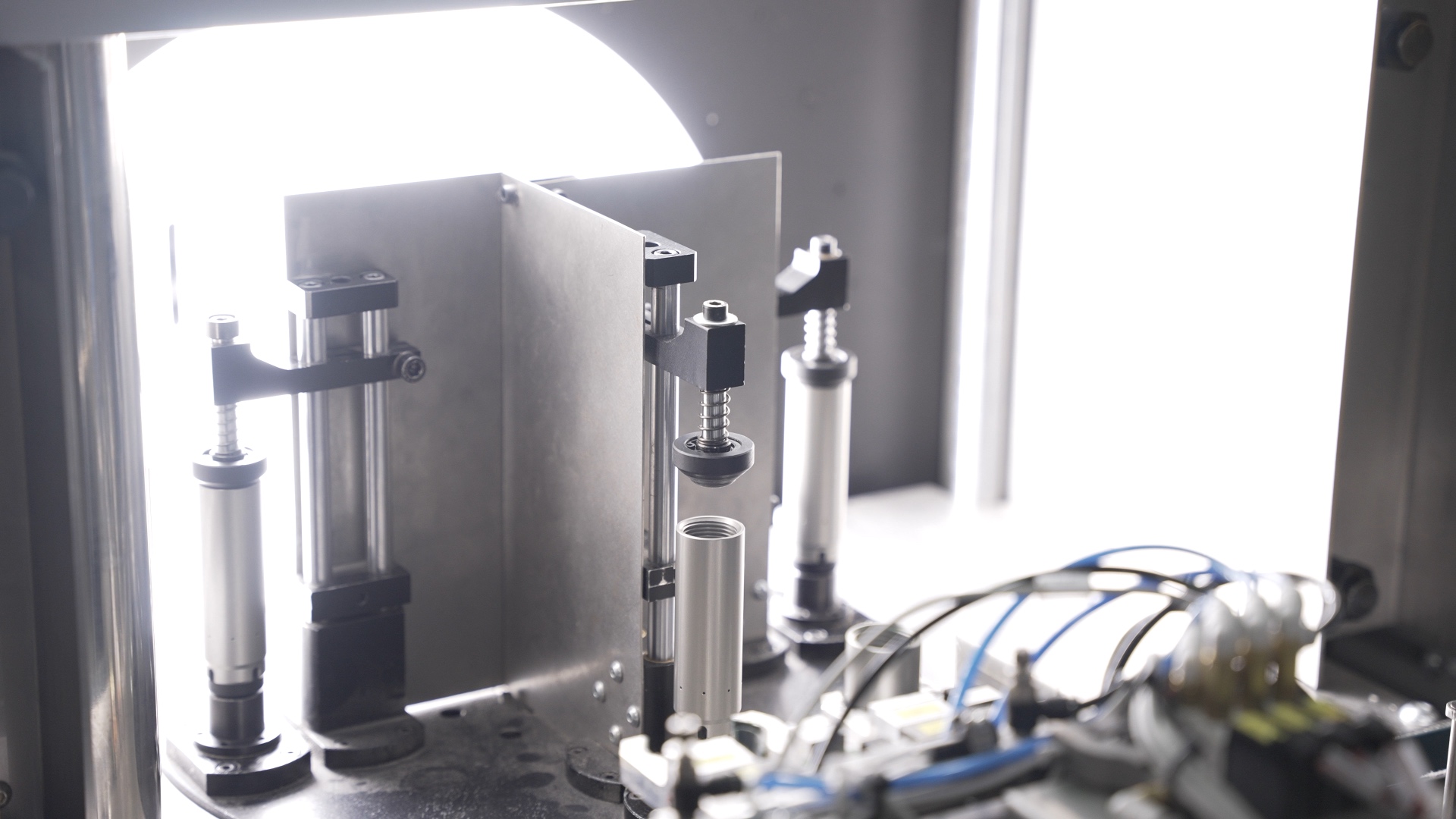

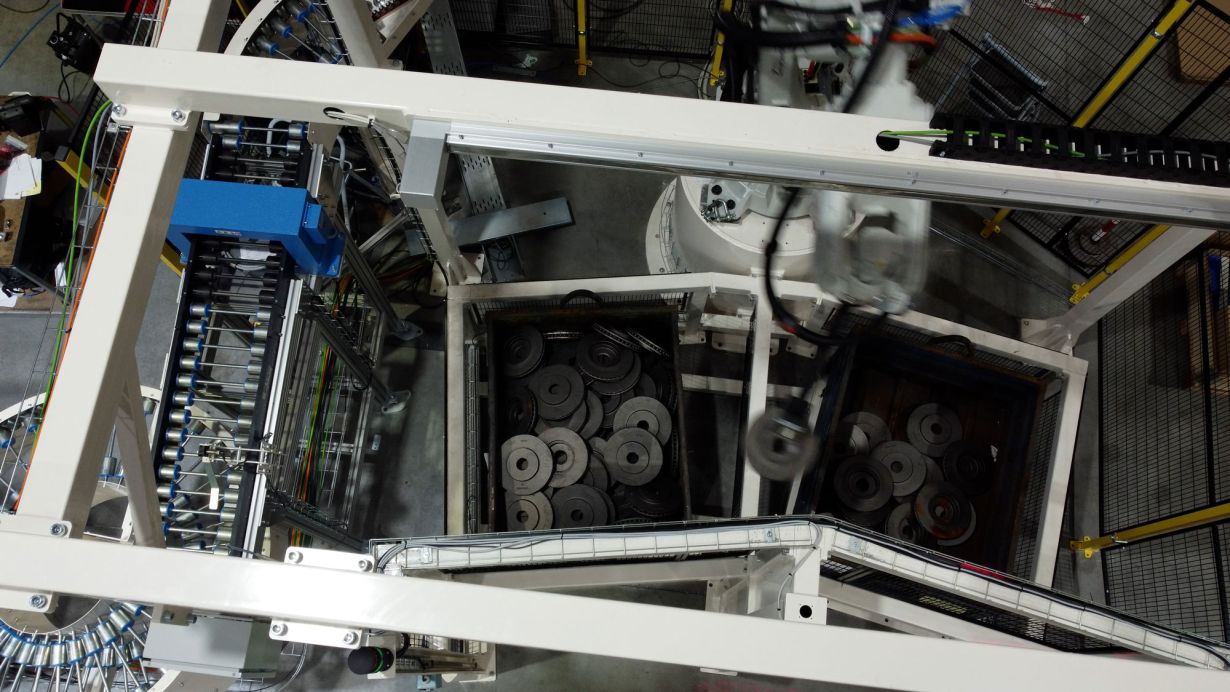

In the first station, two area scan cameras with “cloudy day” or dome lighting are used to avoid reflections and shadows, generating uniform illumination to acquire 3D images of the top and bottom of the part, enabling the detection of surface defects, impacts, and chip residues. A semi-automatic mechanical system positions the part correctly for both image acquisitions, allowing the system to capture, analyze, and subsequently classify the part as OK or NOK.

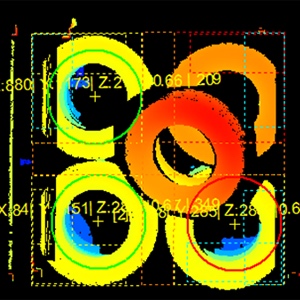

In the second station, a linear Trevista system with segmented lighting is used. A mechanical system rotates the part to capture images of the entire surface, acquire the part’s relief with a 3D effect, and identify possible defects. Using Deep Learning vision, once the full surface image of the part has been acquired, it is analyzed by the Deep Learning software. This technology detects even the smallest defects or material residues despite their variability, while operating quickly and significantly reducing false rejects. This inspection line, composed of two vision systems, inspects approximately 18,000 parts per day.

The main benefits highlighted by Baldomero Ventura following the implementation of these vision systems are:

- Product reliability Ease of inspection using Deep Learning.

- Thanks to artificial intelligence, it is easy to detect imperfections or dirt despite their variability, making it ideal for these parts.

- Very simple Deep Learning system programming.

“We are very pleased with the collaboration and would recommend Bcnvision because they have helped us reduce false rejects and because we consider their vision solutions and products to be the most reliable on the market today,” says Francesc Monleón. At the Bcnvision Group, we are proud to be part of success stories like this one. Thank you for trusting Bcnvision.