Mafrica was founded over 50 years ago in Sant Joan de Vilatorrada, Barcelona, to offer a wide range of meat products, from slaughtering to packaging, ready for supermarket shelves.

It has three different brands offering sausages and pork, lamb, and beef products.

Today, the second generation of the founding families continues to manage the company, combining tradition and innovation, research, and environmental responsibility, collaborating closely with technology research centers and leading engineering firms in the sector.

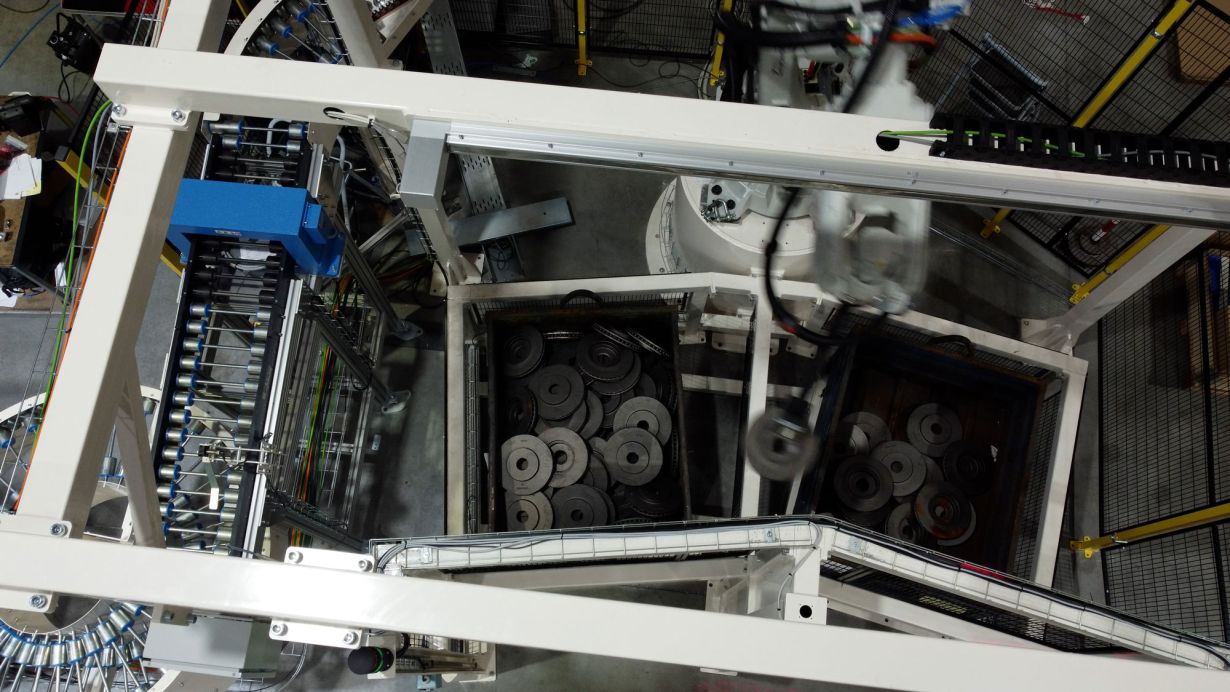

Mafrica operates multiple facilities, including slaughtering, cutting, slicing, and processing rooms, equipped with machinery for vacuum packaging, skin packaging, and preparing pre-packaged products, as well as a sausage factory and several refrigerated chambers.

From its inception, Mafrica has focused on making its facilities a model of hygiene and food safety, complying with strict European regulations and constantly incorporating the latest industry technologies to ensure production processes meet all requirements for animal welfare, product traceability, and efficiency. Its commitment to technological advancement and improved productivity led Mafrica to recently install artificial vision systems for the classification of trays before heat-sealing, specifically in the cutting and packaging room. Initially, whole meat pieces undergo a superficial freezing process to enable clean and precise cuts. Once sliced, they are manually placed in three tray sizes—large, medium, and small—depending on the type and quantity of product.

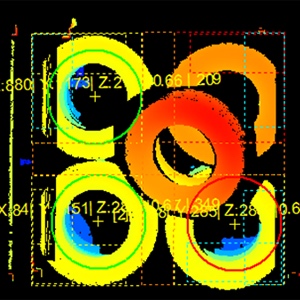

Once filled and just before heat-sealing, Nevitec Visión Technologies’ Atria solution from the Bcnvision Group analyzes all trays using image processing. Currently, there are three AI-based vision stations, which use Deep Learning to:

- Classify trays by size (large, medium, and small).

- Detect the angle at which trays arrive on the conveyor to determine if they can correctly enter the heat-sealing station.

- Check the fill percentage of each tray, ensuring that only trays meeting minimum standards are processed.

Thanks to this classification, trays are correctly distributed by size across the heat-sealing stations. If a tray does not meet acceptable standards for fill level or angle, it is diverted to a repositioning area, where it is refilled and/or reoriented to enter the closing and labeling station correctly before reaching supermarket shelves.

For Nevitec Vision Technologies, collaborating on successful projects like this is a pleasure. The CheckSorter solution, like all Nevitec systems, operates using Artificial Intelligence applied to vision. Configured via Deep Learning, it simulates the human brain’s functioning, enabling the camera to identify product characteristics and classify them while tolerating variations that may affect classification. In short, it combines the reliability of artificial vision with the flexibility and tolerance of human vision.

This vision system can be integrated with additional modules to expand CheckSorter’s functionality, including foreign object detection, OCR reading of label references, X-ray inspection, metal detection, and weight control, among others.

“This project allowed us to see the real capabilities of Deep Learning-based machine vision. We now have other projects on the table to evaluate for plant implementation. Projects like this would hardly be possible with traditional vision systems—they would be more expensive, some unfeasible, and their deployment much slower. Nevitec’s response has been excellent, both in results and in the dedication of their team. They understood the project from the start and adapted to our needs during testing and commissioning. This will certainly not be the last time we collaborate with them.”

Jordi Martí, Manager of Mafrica