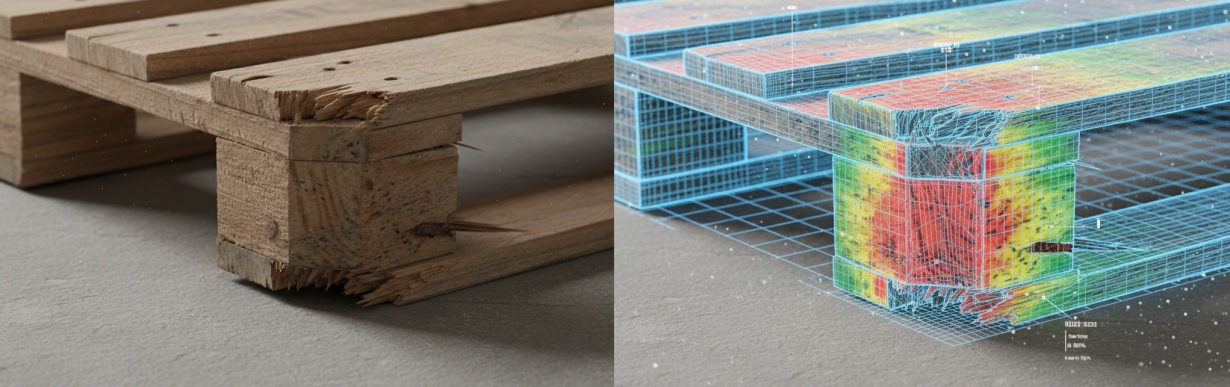

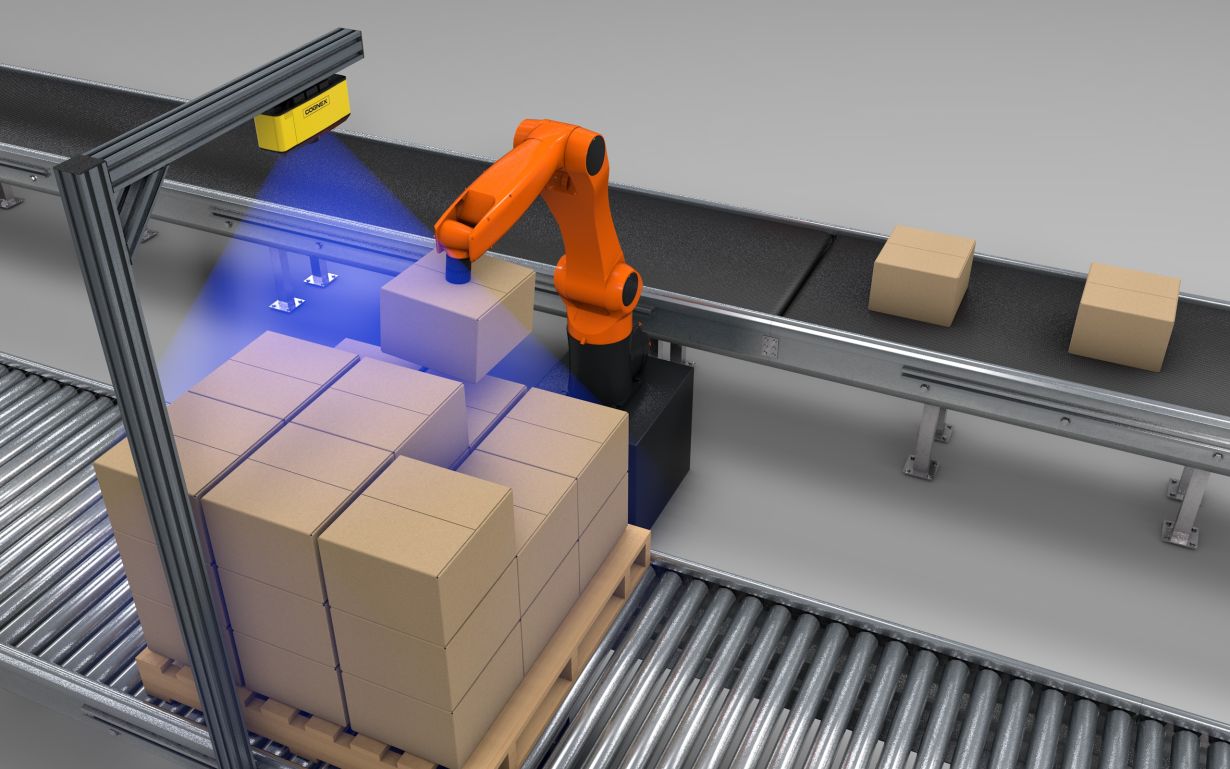

Full pallet reading with machine vision introduces a higher level of precision and control in the handling of grouped pallets. Using smart cameras and specialized software, this technology can inspect and verify every unit on the pallet, ensuring correct code identification, product condition, and exact placement of each item—all in real time and with higher reliability than conventional systems.

Machine vision not only speeds up the control and validation process but also allows immediate detection of possible damage, labeling errors, or issues in product grouping, contributing to full traceability and consistent quality in every shipment. Its technology is flexible and can read 1, 2, 3, or 4 sides of a pallet, regardless of orientation or packaging type.

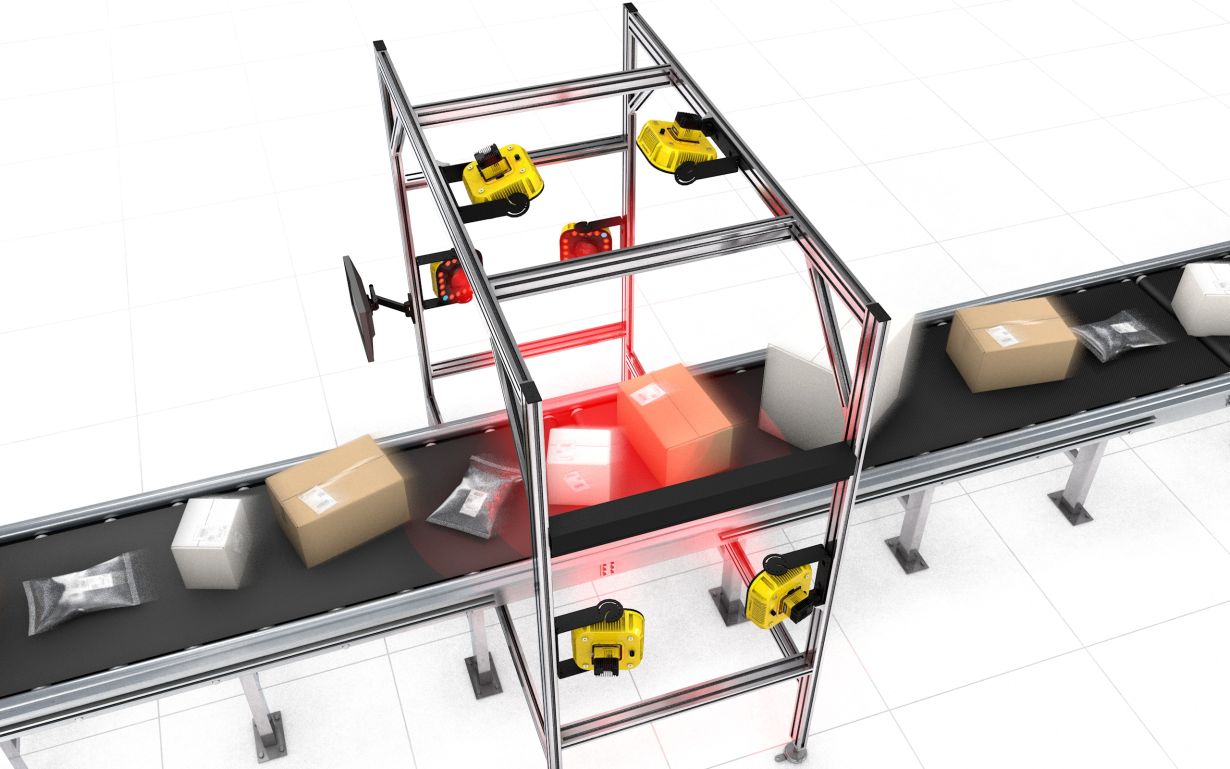

It includes three Pallet Scanning modes to adapt to different logistics needs:

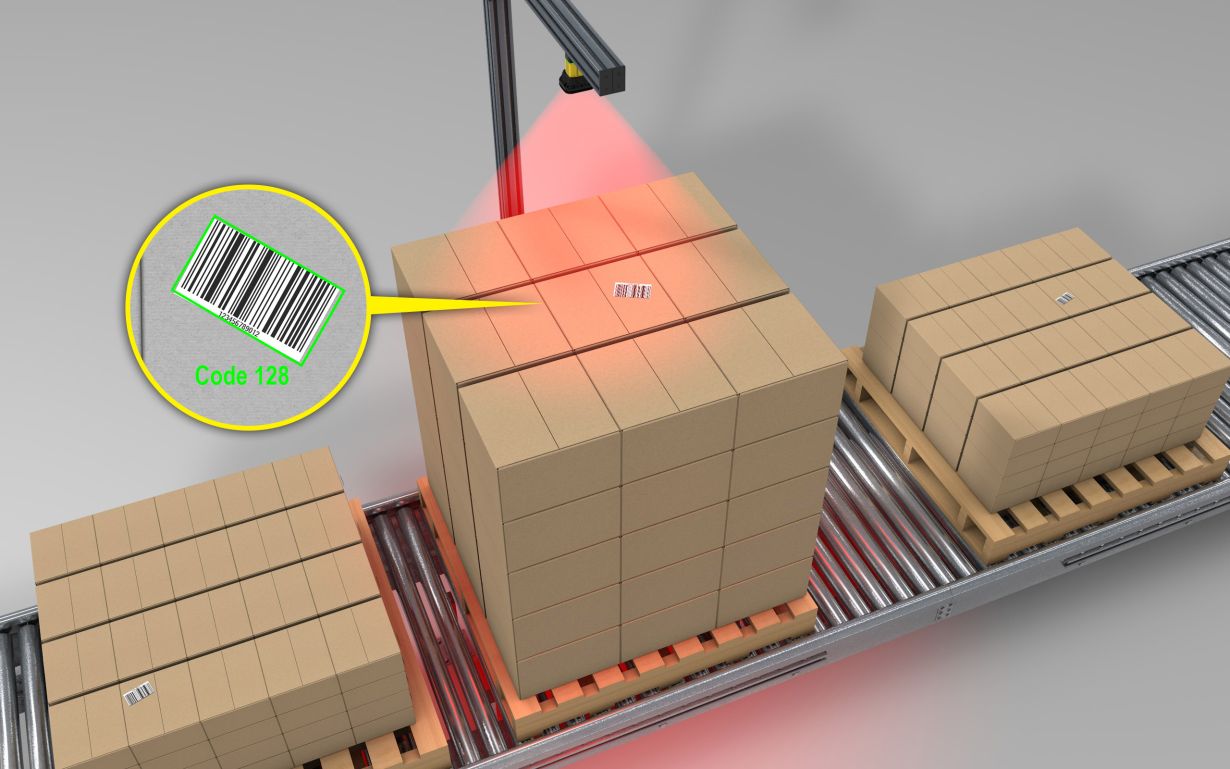

Pallet Scanning

Standard reading of pallet codes to verify references and traceability within the plant. Reads 1, 2, or 4 sides of a pallet at the same station. Easy installation, flexible configuration, and wide fields of view with a single system.

Dock Door

Multi-code reading of pallets from 1, 2, or 3 sides and variable height at warehouse entry or exit, ensuring that shipped or received goods match the documentation.

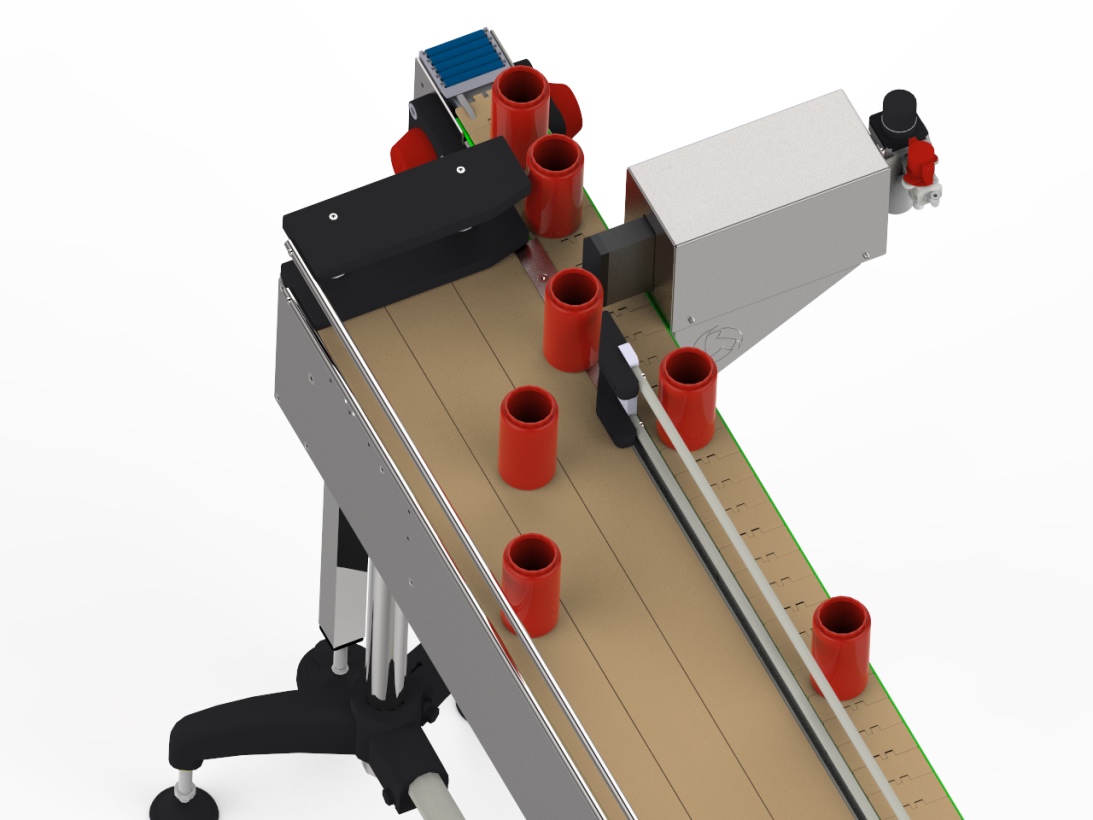

Shrink Wrap

Reading multiple codes even when pallets are wrapped in shrink film, avoiding identification errors due to packaging. Multi-code reading on the pallet wrapper. Depending on pallet configuration, one or more readers may be required.

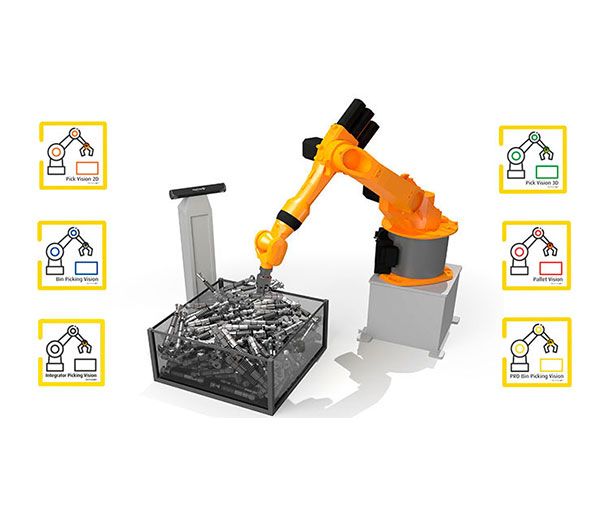

Additional inspections can also be included:

- Weight

- Volumetric calculation of the pallet.