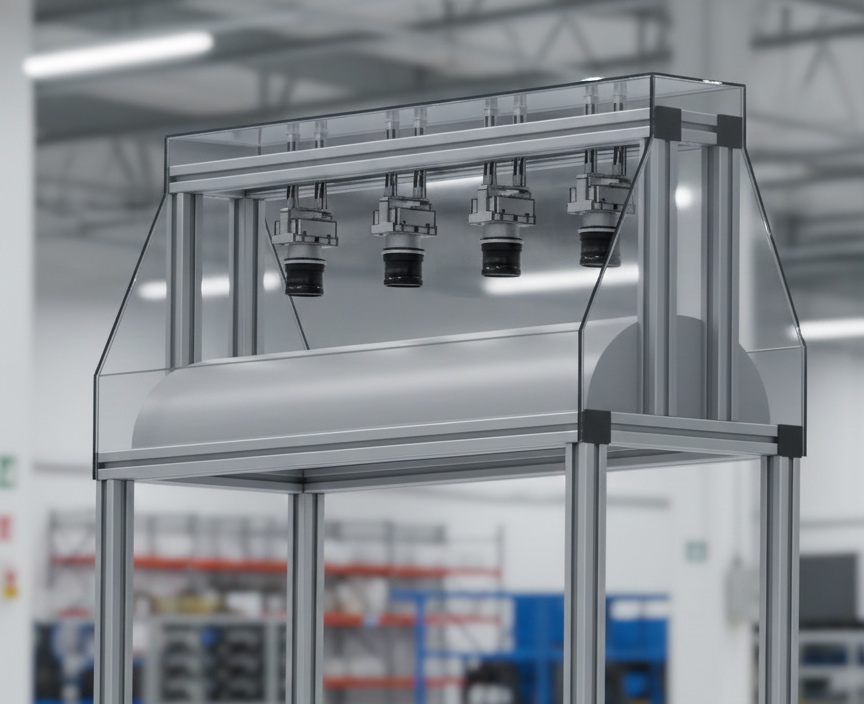

AirDryer Can offers a perfect solution for problems with moisture, condensation and water from cleaning cans. As the system has an open motor, it can be quickly installed on existing lines. The drying system can be placed on one side of the line, and this versatility facilitates rapid installation of the system.

Depending on customer requirements, the systems can be:

*RM System: Open drying system.

*EL system: Semi-closed drying system that includes motor panelling.

- Reduces the acoustic impact of the motor to levels in accordance with regulations.

- Increases motor protection with a second filter.

**LNL system: Fully enclosed drying system.

- Reduces the overall acoustic impact to levels in accordance with regulations.

- Increases motor protection with a second filter.

- Prevents splashing and allows water collection.

*The noise levels of RM and EL systems can be between 85 and 95 dB(A).

**Fully enclosed systems are typically between 78 and 82 dB(A), depending on power and speed.

Hardware

The AirDryer Can is specifically designed to dry aluminum cans, either prior to date coding or before downstream packaging. Using a compact centrifugal blower, the system is suitable for line speeds of up to 120,000 cans per hour.

The system is optimized to facilitate installation, operation, and maintenance. It is capable of drying different can formats, removing up to 99%* of residual water.

*Figure achieved after rigorous product testing at dedicated test facilities.

Features include:

- “Can Dryer” system, mounted on top of the conveyor to dry either the can tops or bottoms (after the twister).

- Anodized aluminum or stainless steel air knives for drying the sides of the cans.

- Noise levels of 91 dB(A) without the polyethylene spray enclosure and 89 dB(A) with it.

- The equipment can be supplied with acoustic insulation for the blower or with the entire unit fully enclosed.